Actisol’s story started nearly 60 years ago. Created by two pioneering and passionate men, the company has endured over time and continues to innovate while respecting the soil and agronomic rules.

Click on a date and learn more about our origins!

In 1963, the two men’s teams met for the first time at Saint Martin en Haut in the Monts du Lyonnais.

On one side, Raoul LEMAIRE, a grain trader, wheat breeder and baker, who also created the first ‘organic bread’. On the other side, Jean BOUCHER, Head of the Loire Atlantique Plant Protection Services, who was passionate about soil life and very concerned about the consequences of the use of chemicals in farming. At the time, most people considered the soil as a support and not a living environment.

In early 1964, Jean BOUCHER partnered with Raoul LEMAIRE. This marked the beginning of the LEMAIRE-BOUCHER method.

One of the avenues of thought of this method was to not turn the soil over to leave the arable and fertile layer of soil on the surface and not bring up the less fertile or even sterile lower layer (certain sands or clays). Leaving the bacteria and fungi in their environments, the aerobic bacteria in the topsoil and the anaerobic bacteria in the deeper layers, was the concern.

An alternative to ploughing needed to be found in order to allow air and water to enter the soil without weakening the structures.

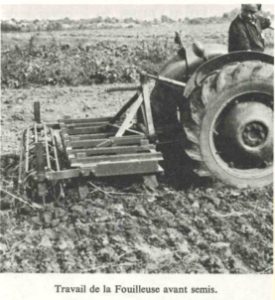

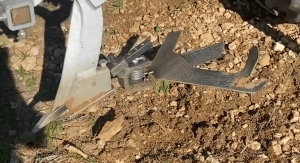

A first tool, called “LA FOUILLEUSE” (soil prober), was developed and marketed in Saint Sylvain d’Anjou (49). The first cracking tooth was developed in a forge on the banks of the Loire.

With a width of two metres and weighing 255 kg, the soil prober was a versatile tool combining robustness and ease of use. Both stubble working and soil loosening were possible thanks to its forged coulters the ends of could be fitted with either a blade for shallow work or a cracking shoe for deep work. Initially equipped with a safety bolt, the tool quickly showed its limits, except in market gardening and vineyards.

In 1970, Raoul LEMAIRE and Jean BOUCHER decided to rename the ‘Fouilleuse’ as Actisol, in correlation with the bases of the LEMAIRE-BOUCHER method: Actisol for the tool that activates the soil.

As the desire to offer an ever more efficient tool while respecting the life of the soil was anchored in the LEMAIRE-BOUCHER method, improvements in this direction followed very quickly.

From 1974, the Actisol was equipped with double spring equipment, allowing the propagation of a shock wave amplifying the soil cracking phenomenon.

In 1982, Raoul LEMAIRE filed an application with the INPI (French National Institute of Industrial Property), making Actisol a brand in its own right.

Raoul LEMAIRE met Jacques MONIN, Managing Director of the brand new company ELICATH in Briollay (49).

By mutual agreement, Jacques MONIN began selling the Actisol brand nationwide in 1985.

Over the 12 years that followed, Jacques MONIN travelled around France selling Actisol tools and represented the brand at trade shows both in France and abroad. The tool was improved several times and the range adapted to the needs of its customers while striving to respect the soil.

The frames took on fixed widths ranging from 2.50 to 4.20 metres. The first folding pieces of machinery were the CYBELLE, with working widths of between 4 and 6.40 metres. The cracking tooth evolved, and the first generations of B2 and B3 teeth were developed, while the mixteur roller was combined with the cage roller for the first time. Finally, to meet the requirements of certain farmers with particularly abrasive soils, wear parts could be coated with carbide for a longer service life.

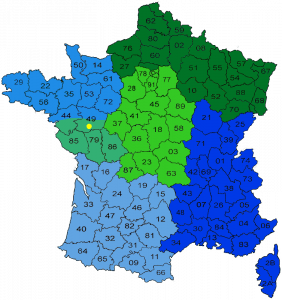

During these years, Actisol durably established itself on the French market.

In January 1999, ELICATH and Actisol took another direction. Gérard Socheleau, Etienne DELAHAYE and Laurent MANCEAU took over from Jacques MONIN who had spent a decade selling thousands of Actisols to field crop and speciality crop (wine, orchards, organic production, etc.) farmers.

Each having specialised in soil preparation techniques for around ten years, their objective was first to develop the sale of Actisol machinery through a network of dealers and second, to expand the offer on the very new market for simplified tillage and organic production.

This was when the range began to be restructured, frames were standardised, and the production process was reviewed in order to store materials and components to produce and anticipate needs and no longer use a just-in-time production process. Perfectionist by nature, Etienne DELAHAYE and Laurent MANCEAU made a point of improving machinery quality.

The two men laid the foundations of Actisol as we know it today…

In the new millennium, there were fundamental changes in Actisol. In order to join an industrial and economic area, the company settled in Cholet (49) where it is still located to this day. This geographical move made it possible to develop local subcontracting meeting the aspirations of the new managing directors.

The Actisol brand became its own representative and a leader in cracking.

In the early 2000s, a domestic retail network was set up with committed partners, which is still in effect today.

Over the next decade, the Actisol range continued to expand to meet the needs and demands of its customers, while remaining faithful to its agronomic values :

HERBASOL

Deep soil aeration

ACTIMIXT

Combined cracking solutions

GAEA

For small working widths

SPARTEA

Wide machinery for large areas of land

GAMME MARAICHAGE

All-round strip preparation

COMBISOL

Extra versatility

ACTIFLORE

Surface soil aeration

SPASS

Large format combined cracking solution

ROLL KROP

For plant cover destruction

In addition to the development of the range, existing machinery was improved. The CYBELLE was equipped with vertical folding instead of horizontal folding, reducing transport width from 3.50 m to 2.50 m. Another notable development was that depth adjustments were no longer manual but hydraulic.

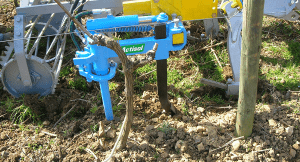

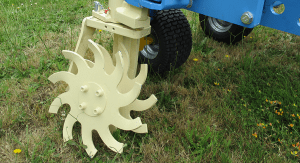

It was also during this decade that the first hydraulic extensions appeared along with between vine tools (mechanical, hydraulic, lump breaker discs, etc.).

To support growth and meet the requirements of the new production process, the store’s storage space grew significantly in 2010. The surface area of the original building increased from 1,000 m² to 2,400 m²:

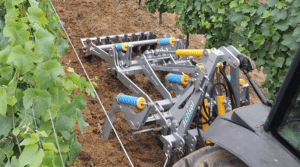

The 2010 extension made it possible to significantly develop the Actisol range. Adapting to the needs of its customers, Actisol developed and modernised seven pieces of machinery for mixed farming and vineyards over this period. Here are a few of them :

SPASS VRH

Semi-mounted wide-width work

ACTIMIXT TRADITION

Next generation single beam

ACTIFLEX

Shallow market garden strip preparation

ROLL KROP VIGNE

Controlled grass cover

MULTEA

For very wide vines

OMNISOL

Grassed vines every other row

LAVANDE

Machinery specially developed for lavender farming

But another new feature facilitating the use of field crop machinery would come out in 2015…

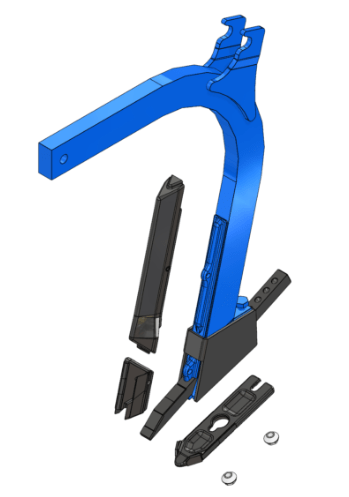

In 2015, a range of parts revolutionising not only the maintenance of future Actisol machinery but also that of old ones was developed.

A real practical and economical leap forward, FISSOL parts were designed and developed for faster assembly and disassembly as well as reduced traction forces and optimised wear volumes for better cost-effectiveness.

Compatible with existing machinery via a simple procedure, the FISSOL concept is part of an eco-responsible approach, close to Actisol values.

At the same time, new machinery was developed for more diversified use. The ECOSOL, previously fixed for weeding paths, could now be adjusted on the right, left, or on both sides.

The LAVANDE and OMNISOL range expanded to adapt as closely as possible to customer needs.

The DEMETER PACK 3 also came out in 2015. The DEMETER PACK 3, a three-beam cracker, allows you to work with a higher soil flow than its big twin-beam brother.

In 2017, Actisol changed management. Freddy SOCCHELEAU was appointed Managing Director. This decision was part of a transfer project guaranteeing the company’s independence. Actisol maintained its agronomic principles at the heart of product development.

A new piece of machinery was also released: the COMBIVARIO tool holder expanded the COMBISOL range for increased versatility and flexibility.

Emblematic models in the field crops range, such as the DEMETER, CYBELLE, and SPARTEA, were also redesigned in 2017. The increase in tractor power was anticipated with a new design and updated structure calculations.

DEMETER :

SPARTEA :

CYBELLE :

Follow our story in real time and join the Actisol community:

facebook

linkedin

twitter

youtube