Soil decompactor or soil cracker ?

Among the machines dedicated to conservation farming, you’ve probably already heard of the soil decompactor and soil cracker. Find out more about these machines below.

What is a decompactor ?

A decompactor is deep soil farming equipment used to break up plough beds. Its straight, rigid teeth, fitted with square bar or blades, usually operate at a depth of between 20 and 30cm, usually under the sole.

The decompactor is often referred to as a “loosener” because it works the soil by lifting or even tearing it up. As it passes through, the soil horizons break up into several pieces, creating hollow areas and destructuring. This action can also lead to significant smoothing if the teeth is fitted with a blade that is too wide or if conditions are poor. So it’s important to identify your soil problems before using this type of equipment.

Finally, the decompactor is regularly used in combination with seeding tools, as it is ideal for “lifting” tractor wheel tracks. At a moderate depth, damage to the soil is reduced.

The differences between a decompactor and a soil cracker

Decompactor or soil cracker ? It’s sometimes difficult to tell the difference between these two items of equipment, even though they are opposites in terms of agronomy. A decompactor is often presented as the equivalent of a cracking equipment.

The decompactor

As mentioned above, the decompactor requires a great deal of tractive power due to its deeper work and the weight of certain types of equipment. As a result, fossil fuel consumption is higher and greenhouse gas emissions are proportionately equivalent. This equipment aerates the soil, improves drainage and breaks up plough soles.

But decompacting the soil requires extra care. We strongly advise against decompacting with heavy equipment in wet conditions, as this can smooth the soil and cause it to settle. Breaking up the soil when a decompactor passes over it mixes up the horizons and disrupts the life of the organisms living there.

The soil cracker

The soil cracker works vertically with the Actisol straight teeth (20 to 30cm), creating a fissuring wave without turning the soil over, so without disturbing the horizons. It will generate a slight expansion of the surface which will encourage exchanges with the atmosphere. A decompactor, on the other hand, can leave blocks that are difficult to rework in dry conditions.

This action oxygenates the soil and encourages mineralisation by preserving the living organisms in place. It therefore restructures the soil gently. Its lower traction requirements help to reduce fossil fuel consumption and, by extension, greenhouse gas emissions.

Why choose a soil cracker cracker over a compactor ?

Decompacting your soil with a soil cracker is part of the logic of conservation agriculture. The main objective is to respect the natural organisation of the soil. The aim is to decompact the soil while preserving its horizons.

This technique is appreciated by agrobiologists because it :

- It preserves the soil’s fertile topsoil on the upper horizon. This layer, which is richer in humus, remains available for crops. This humic horizon, rich in plant matter, must remain in contact with the atmosphere to insulate and protect the soil.

- Leaves in place the lower layers of the soil, which are less fertile and sometimes even sterile.

- Leaves bacteria in their natural environment, with aerobic bacteria needing oxygen in the topsoil and anaerobic bacteria living without oxygen in the deeper layers.

- Loosens the soil in depth and width without refining it. Soil that is excessively fragmented will settle more easily with water. This reduces the risk of compaction.

- Respects the biodiversity of the soil and makes it alive and fertile.

So the use a soil cracker is part of a desire to work with the soil and not just see it as a support. The aim is to allow the soil to nourish the plant and create the conditions for deep root development. It’s also about working in correlation with the living organisms in the soil that help crop yields by providing shelter and cover.

What’s more, the Actisol cracking teeth is extremely versatile: as well as being able to fissure the soil, it can scalp, stubble and prepare a seedbed. An Actisol teeth can be fitted with shoes, wings or ploughshares as required.

Choose the right technique for your soil

So how do you choose the right technique for your soil?

The first step is observation. By carrying out a study of your plots you will then be in a position to opt for the most suitable approach. There is no single universal technique for all needs.

Several methods exist to help you get a better view of your soil: the penetrometer, the spade method, the Pépone method… We explain it all in our dedicated article: How to study your soil to adapt your work to it?

Actisol: the inventors of cracking

Actisol was the forerunner in cracking in the 1960s. It was thanks to two people with a passion for soil life that the first equipment was developed. The Lemaire-Boucher method (named after its founders) involves working the soil without turning it over. In this way, the non-fertile layers do not rise to the surface, leaving the upper layers containing all the biodiversity in place, so that it can aerate, mineralise and fertilise the first horizon.

The Actisol brand was registered by Mr LEMAIRE, with the etymology “Actisol, the tool that activates the soil“.

The Actisol teeth is designed to work in this way. The pressure exerted at its tip is around one tonne. On a chassis, this teeth taps and produces impacts that propagate 20 to 25 cm around it to break up the ploughing surface.

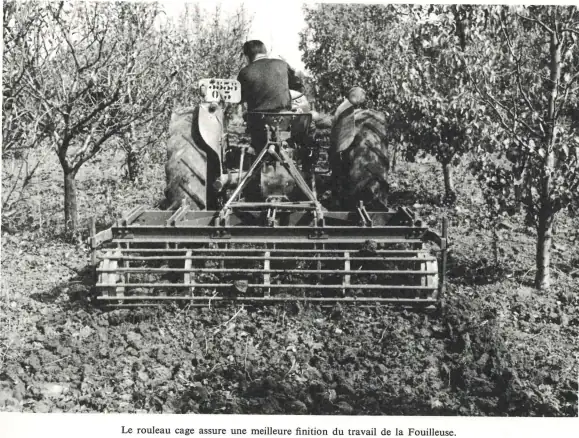

The Actisol teeth softens the structure to a depth of up to 30 cm, depending on conditions, while the double tandem roller mounted at the rear of the chassis ensures stability and depth control. The soil is levelled and aerated after the equipment has passed over it, and retains its full bearing capacity.

There is a wide range of soil crackers to suit different conditions of use. We recommend that you consult us when choosing your soil-breaking equipment, so that we can target a model suited to your needs.