Description

| Name | Beams and spacing | Frame | Hitching | Modules | Extensions | Working width | Weight |

|---|---|---|---|---|---|---|---|

| STS 304 | 1 | Fixed | Cat.3 | 4 | 300 | 675 | |

| STS 306 | 1 | Fixed | Cat.3 | 6 | 300 | 870 | |

| STT 456 | 2 spacing 120 | Telescopic | Cat.3 | 6 | 2 | 450 | 1105 |

| STS 304 RH | 1 | Fixed | Cat.3 | 4 | 300 | 930 | |

| STS 306 RH | 1 | Fixed | Cat.3 | 6 | 300 | 1125 | |

| STT 456 RH | 2 spacing 120 | Telescopic | Cat.3 | 6 | 2 | 450 | 1300 |

Originally developed in the United States and Canada, the Strip Till is becoming increasingly popular in France. At Actisol, we are developing machines that will enable you to embark on this technical route. This is in line with our DNA: soil conservation.

What is Strip Till?

Strip till is a cultivation technique developed in the 1980s in North America. It appeared in France less than ten years ago and is one of the simplified tillage methods.

The basic principle is to work only the sowing row before using the seed drill. Suitable for all row crops, it involves preparing the seedbed in the residue of the previous crop or plant cover. A disc harrow opens several furrows 10 to 25 cm wide and 5 to 25 cm deep. The crop debris is left in the inter-row to create a mulch.

What are the advantages of the Strip Till method?

The Strip Till method has a number of advantages. First of all, it limits the number of passes made by equipment over the plots and therefore reduces the risks of compaction

Why use Strip Till ?

Unlike conventional tillage, this technique conserves the soil moisture necessary for the growth of seedling emergence and prevents the washing thanks to inter-row residues. This prevents weeds from germinating, limits erosion and maintains the soil’s bearing capacity. Crops sown in strip till showed greater ease of establishment and root development, since this technique favours the soil heating on the seed line.

Working on precise rows allows localised fertilisation and a reduction in doses. This is a significant economic gain, as is fuel consumption, which is reduced by shallow tillage.

In conclusion, by working without disrupting the horizons or dissolving the organic matter, while reducing the workload, compaction and consumption of fossil energy, Strip Till respects the life of the soil and is in the vein of conservation agriculture.

An effective method all year round

The ideal season to use Strip Till depends largely on the type of soil in the plot. As the method only requires one pass, you need to be vigilant. It must be carried out on reconsolidated soil, otherwise there is a risk of smoothing.

Depending on the type of soil

On clay soils (composed predominantly of clay), it is preferable to use the equipment during the autumn/winter period.

Bear in mind that this technique is best used at times of the year when soil moisture is most favourable. The working speed for Strip Till, without combining with another tool, varies between 8 and 12 km/h.

Strip Sol: the Strip Till method by Actisol

Actisol has developed Strip Sol equipment that can be used in combination with the fine, fluid tines of the Actimixt or Spass. These crack the soil vertically and horizontally using shock waves.

How our equipment works?

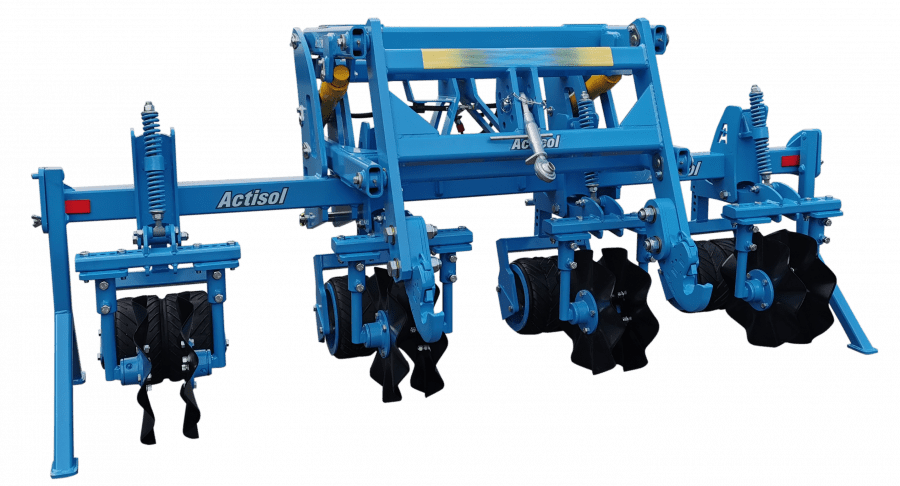

The Actisol Strip Till consists of a fissurator fitted with opening discs that cut the vegetation to make it easier for the tine to pass through and avoid the rake effect. It limits uprooting and promotes a clean sowing line.

The teeth cracks the soil to create a deep root system for the future seed, while maintaining a good structure without disrupting the horizons.

At the rear of the fissurator, the Strip Sol modules are completely independent and serve to support the seed line using a pneumatic wheel system, essential for even emergence.

Embossed discs behind the wheels work the seed line to create an optimum seedbed. Mounted on a parallelogram, these two elements have asymmetric pressure adjustment with height adjustment for the support wheels and discs, which also have orientation adjustment.

The reduced overhang of this agricultural equipment means that it can be used with a seed drill. The parallelogram linkage reduces the overall size of the machine, making it safer to transport and manoeuvre.

Choose Actisol for your Strip Till

Thanks to its design tailored to the needs of the Strip Till method and backed up by Actisol’s recognised expertise, our Strip Sol is the essential equipment for a complete and respectful treatment of your floors.

Our specialists are perfectly familiar with the characteristics of the Strip Till method and the benefits it brings. We have used this in-depth knowledge to develop our machine dedicated to this technique.

We invite you to contact our team if you would like more details on our solutions before adopting one of our products.